Manufacturing

Fasion Art International

Production Capacity

Our Production capacity is 300 tons per month, These goods are primarily high value added items. The company is constantly striving to enhance it’s production capacity. To meet and exceed current market demands.

Production Capacity

Our Production capacity is 300 tons per month, These goods are primarily high value added items. The company is constantly striving to enhance it’s production capacity. To meet and exceed current market demands.

Product Development

We believe high quality yarn and fabric are the most crucial element in manufacturing superior terry products. We employ an R (&D team of engineers to constantly follow the latest developments in the world of textiles. Track trends at leading international fairs and propose an expanding archive of alternate fabrics to clients.

Our fabrics department is committed to fulfill your customized requests & to offer their expertise at every stage of the purchasing and sampling process, Upon requests our sampling department carefully designs & develops the highest quality samples as per

Product Development

We believe high quality yarn and fabric are the most crucial element in manufacturing superior terry products. We employ an R (&D team of engineers to constantly follow the latest developments in the world of textiles. Track trends at leading international fairs and propose an expanding archive of alternate fabrics to clients.

Our fabrics department is committed to fulfill your customized requests & to offer their expertise at every stage of the purchasing and sampling process, Upon requests our sampling department carefully designs & develops the highest quality samples as per

Weaving

Presently we’re weaving terry towels starting from 280 GSM to 700 GSM in plain Dobby % Jacquard designs. Our weaving setup allows us to do a wide range of terry products in all possible sizes with a minimum level of rejection and of only the highest quality.

Weaving on High – tech Latest Air jet looms & In house Vamatex (Dynaterry silver) Shuttle Less Looms & Auto looms using top of the line yarns including ring spun, carded, combed, PIMA, Egyptian cotton, Zero Twist, Low twist, Organiz , Ultra Low twist & Bamboo Yarns.

State of the art in-house dyeing on the best atmospheric softlow dyeing machines & high Temperature machines with conveyor dryers & continuous tumbler for finbishing to achieve uniform pile information, shrinkage control, softness & absorbancy.

Weaving

Presently we’re weaving terry towels starting from 280 GSM to 700 GSM in plain Dobby % Jacquard designs. Our weaving setup allows us to do a wide range of terry products in all possible sizes with a minimum level of rejection and of only the highest quality.

Weaving on High – tech Latest Air jet looms & In house Vamatex (Dynaterry silver) Shuttle Less Looms & Auto looms using top of the line yarns including ring spun, carded, combed, PIMA, Egyptian cotton, Zero Twist, Low twist, Organiz , Ultra Low twist & Bamboo Yarns.

State of the art in-house dyeing on the best atmospheric softlow dyeing machines & high Temperature machines with conveyor dryers & continuous tumbler for finbishing to achieve uniform pile information, shrinkage control, softness & absorbancy.

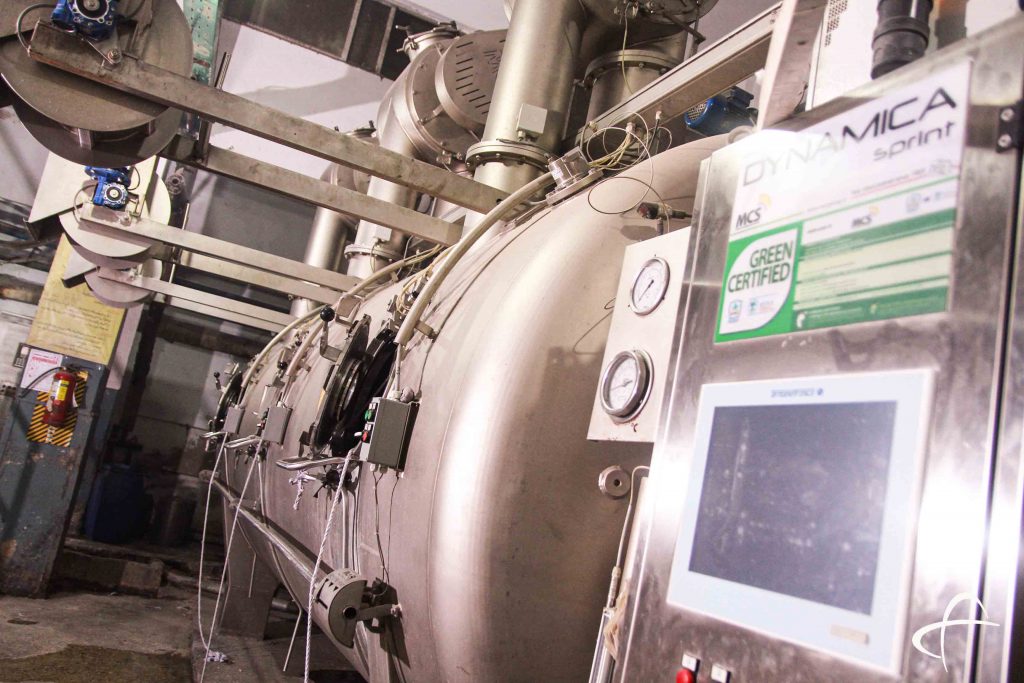

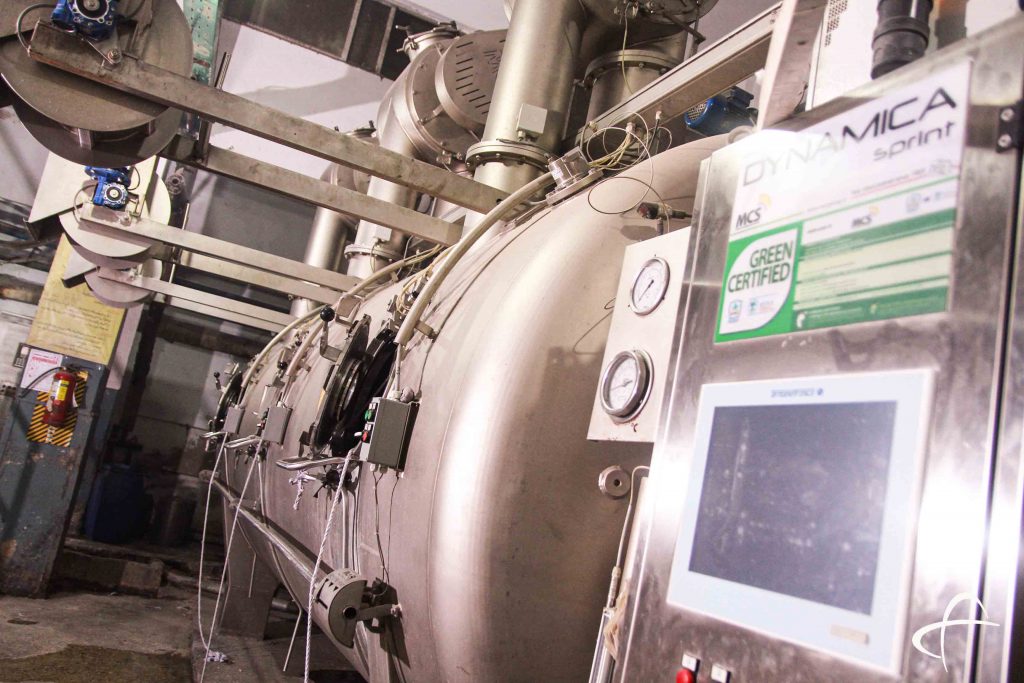

Dyeing & Processing

We are only using modern & Well equipped machinery for dyeing and finishing of our product. With a vision to become no 1 in the country. All our processing machines are exclusively terry based and very well maintained. We have recently installed top of the lins MCS (Italy) towel dyeing machines along with Pentek (Italy) towel finishing + Softening machine. These machines besides giving top of the line quality are also eco friendly by consuming less water + less energy.

Dyeing & Processing

We are only using modern & Well equipped machinery for dyeing and finishing of our product. With a vision to become no 1 in the country. All our processing machines are exclusively terry based and very well maintained. We have recently installed top of the lins MCS (Italy) towel dyeing machines along with Pentek (Italy) towel finishing + Softening machine. These machines besides giving top of the line quality are also eco friendly by consuming less water + less energy.

Cutting & Stitching

Our cutting department uses high end cutting machines to guarantee maximum yield and accuracy. We have Azimo (Turkey) augto length hemming and semi- auto length hemming, and semi – auto looking machines to achieve best finishing on towels. Operating as a quality focused manufacturer for more than 20 years, Fashion Art International is recognized for its impeccable workmanship even with every complex design on computerized machines. We are proud to promise our clients tailor made end products even if this involves more labor intensive work.

Cutting & Stitching

Our cutting department uses high end cutting machines to guarantee maximum yield and accuracy. We have Azimo (Turkey) augto length hemming and semi- auto length hemming, and semi – auto looking machines to achieve best finishing on towels. Operating as a quality focused manufacturer for more than 20 years, Fashion Art International is recognized for its impeccable workmanship even with every complex design on computerized machines. We are proud to promise our clients tailor made end products even if this involves more labor intensive work.

The Quality

Our Quality Assurance system consists of several thorough stages: Raw yarn, woven fabric, inspection followed by dyed fabric examination, fabric spreading & cutting inspection, pre sewing assembly and final inspection by a team of qualified quality control experts. All staged are carried out in-house to guarantee complete oversight and control over pre-shipped products.

The Quality

Our Quality Assurance system consists of several thorough stages: Raw yarn, woven fabric, inspection followed by dyed fabric examination, fabric spreading & cutting inspection, pre sewing assembly and final inspection by a team of qualified quality control experts. All staged are carried out in-house to guarantee complete oversight and control over pre-shipped products.

Plot # LA-3/1, Block-22,F. B. Industrial Area,

Karachi – Pakistan

+92 (213) 6366663-5

info@fashionartinternational.com

Copyright © 2021 Fasion Art All rights reserved.